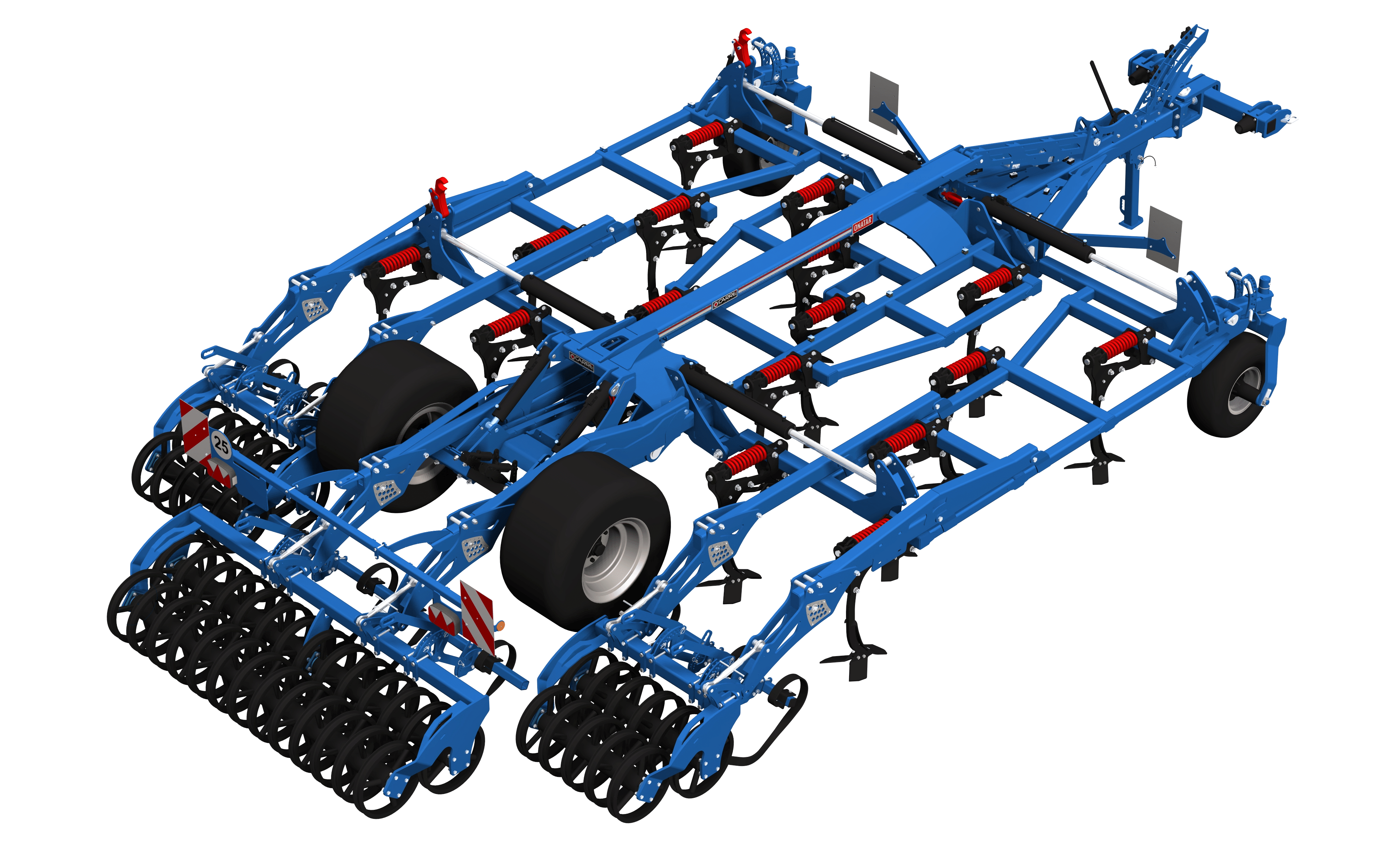

Un véritable châssis traîné conçu pour les grandes surfaces.

Ses grandes largeurs conviennent parfaitement pour les grandes plaines et son châssis de 4 rangées permet un flux de terre et un mélange optimal.

Le déchaumeur à dents ONATAR NEO trainé peut être équipé de la dent non-stop mécanique à double ressort développé par CARRÉ.

Le châssis est verrouillable au transport et au travail par des pièces mécaniques assurant une grande stabilité et une grande sécurité sur la route.

Il est homologué pour la route par la DREAL.

Ses pneumatiques offrent un profil au marquage réduit pour limiter les compactions de sol.

En standard la dent est équipée d’une pointe de 120, d’un versoir twist de 100 et d’aileron droite/gauche de 300 mm.

Disponible de 5 à 8 m !

Double sécurité de verrouillage hydrau-mécanique (transport et travail)

Double sécurité de verrouillage hydrau-mécanique (transport et travail)  Dent non-stop mécanique à double ressort modèle OLLADRA Dégagement 840 mm – Dégagement vertical 250 mm Effort de déclenchement à partir de 550 kg

Dent non-stop mécanique à double ressort modèle OLLADRA Dégagement 840 mm – Dégagement vertical 250 mm Effort de déclenchement à partir de 550 kg