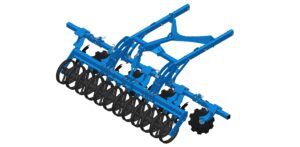

Le déchaumeur à dents ONATAR NEO permet une bonne polyvalence de travail en superficie ou en profondeur.

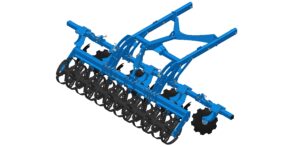

L’espace entre chacune des poutres et des dents facilite l’évacuation des débris et flux de terre.

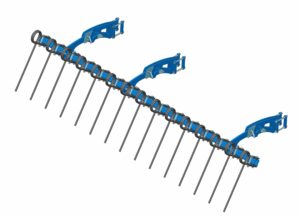

La dent est maintenue par un ergot pour qu’elle garde toujours sa position

L’ONATAR NEO offre un dégagement sous châssis de 840 mm pour limiter les risques de bourrage quelle que soit la quantité de résidus.

Disponible de 3 à 5 m !

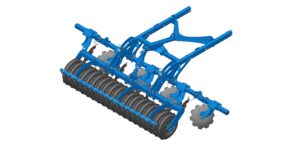

Double sécurité de verrouillage hydrau-mécanique (transport et travail)

Double sécurité de verrouillage hydrau-mécanique (transport et travail)  Dent non-stop mécanique à double ressort modèle OLLADRA Dégagement 840 mm – Dégagement vertical 250 mm Effort de déclenchement à partir de 550 kg

Dent non-stop mécanique à double ressort modèle OLLADRA Dégagement 840 mm – Dégagement vertical 250 mm Effort de déclenchement à partir de 550 kg